Stock audit for Manufacturing units is essential to keep correct inventory records of manufacturing and ensure operational efficiency. Manufacturing unit hubs play a significant role in the Indian economy with 17% of the nation's GDP and over 27.3 million workers. It is an integral and huge part of the economy. It involves processing and refining raw materials, such as ore, wood, and foodstuffs, into finished products, such as metal goods, furniture, and processed foods. It is necessary to conduct a regular stock audit for manufacturing units to reduce the business loss due to fraud or theft and find the error to improve the overall inventory management. Bizfoc is a leading stock auditor company in India who provides stock audit for manufacturing unit service with professional auditors at a reasonable price.

A stock audit is a comprehensive evaluation of a manufacturing unit inventory, accessing both the physical stock and the accuracy of inventory records. In the manufacturing industry, it is very essential to arrange a stock auditor to ensure accurate inventory management and identify any theft, damage or expired inventory. In the manufacturing industry there is a large amount of the raw material that is used to make a finished product, it’s become difficult to verify all the products due to its quantity. To get the proper data of the manufacturing product , the stock auditor helps you to evaluate the manufacturing units, analyze the data which are recorded and also smoothen the business operation.

Many MSMEs conduct Manufacturing unit audits due to management requirements rather than regulatory requirements. The manufacturing stock verification is carried out as prescribed under the Companies (Auditor's Report) Order, 2020, also known as CARO, 2020. The CARO, 2020 applies to the organizations below.

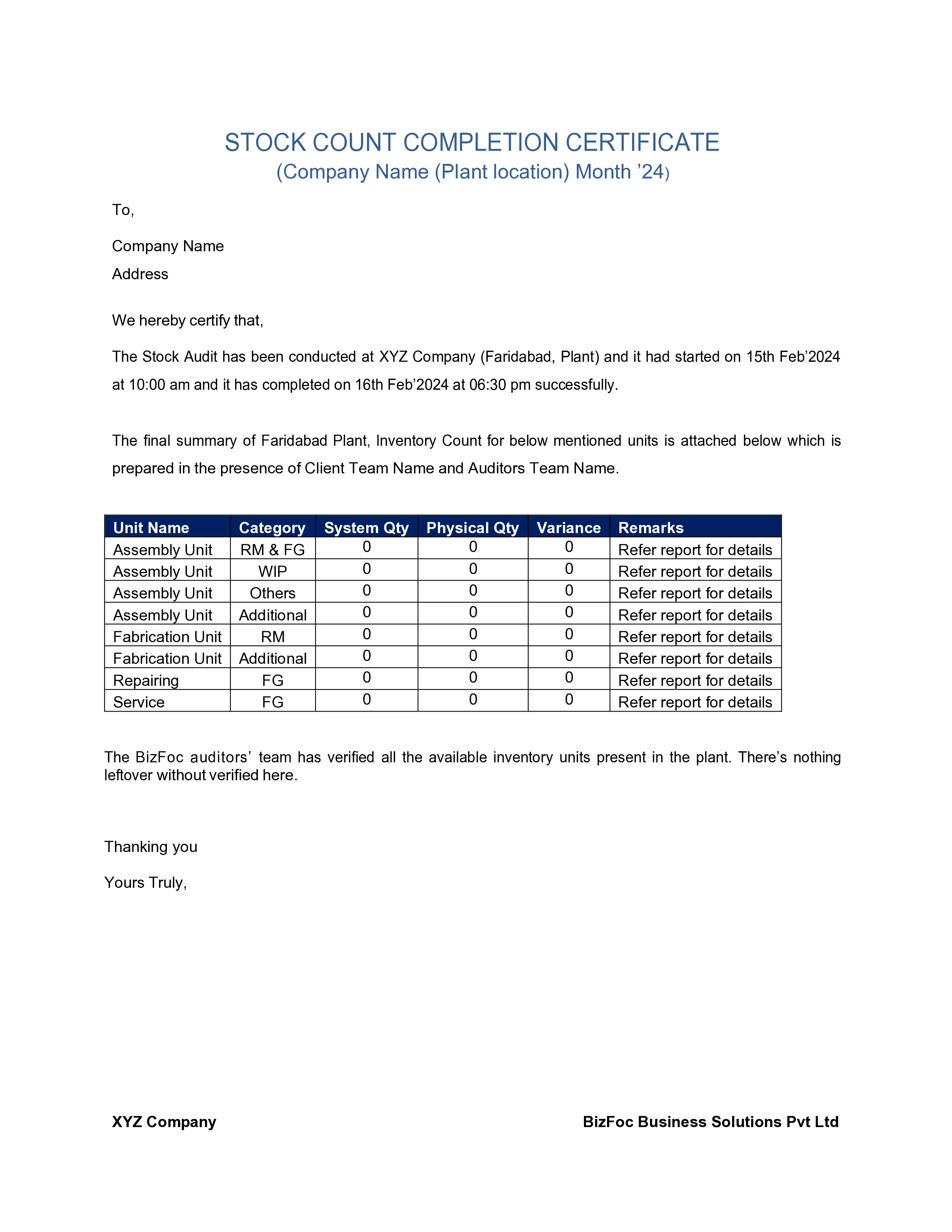

There is no standard format prescribed for the Manufacturing unit audit report. Every company can have their format depending on the purpose of the audit. The auditor's report is usually accompanied by an Excel sheet for conducting any further analysis by the company. The report typically contains the following information:

There is comprehensive guidance on the process of manufacturing unit audit which help to conduct the audit properly:

It is necessary to know the auditing scope, types of inventories, locations, and specific items to be audited. Manufacturing audit timeline must be set, considering the company’s function schedule.

To perform a physical count of the inventory stocks, one must use a systematic approach, like ABC analysis or cycle counting, to ensure comprehensive coverage, and discuss with the appropriate department for the counting process.

Compare the physical counts with the inventory, which is already recorded, write down the outcomes, investigate and reconcile irregularities, and document the reasons for variations post discussion with team on the ground.

Make a report of stock audit findings, which includes any irregularities, and suggestions for enhancement. To give a summary record to high-level management, highlight key outcomes, and recommend appropriate actions.

Inventory audit checklist that is required to be followed for conducting an effective Manufacturing unit audit:

The fee for manufacturing audit services in India can vary depending on various factors such as the number of SKU, night audit, location, days required, and inventory complexity. The stock audit fee starts from ₹2,499 per day, which excludes out of pocket costs and varies with the stock audit scope.

Here are some common challenges faced by the textile and apparel industries:

Bizfoc is a leading manufacturing unit stock audit service provider firm in India with a presence in pan India. The Bizfoc team has more than 10 years of experience in inventory audits, assisting companies like Apple, Toyota Group, Volkswagen Group and Samsung Electronics. Bizfoc provides best-in-class services at transparent pricing with a high degree of precision.

Stock audit helps you understand your company's financial condition. Conducting a regular stock audit for manufacturing units is essential to operate the business efficiently. Audit helps in rectifying the issues, ensure accurate valuation and maintain proper records of each raw material to finish good. If you are looking for a stock auditor for a manufacturing unit in your city then you must know all the process, benefits and fees of the audit. Stock audits not only protect your valuable assets but also foster stakeholder trust.Thus, a stock audit of Manufacturing unit helps improve the organization's profit and loss.

A stock audit report for a manufacturing unit is used to capture the facts or information acquired during a stock audit concerning the company’s existing stocks. Annual audit reports include critical information that firms employ in their financial accounts.

Stock audit helps to maintain inventory accuracy, prevent loss or damages, ensure compliance, and support in making decisions.

Stock audits for manufacturing units are recommended to be conducted regularly, with full annual and cycle counts monthly.

Inventory auditors oversee and match the inventory record to ensure the accuracy of the physical data. They review and analyze the inventory data with the actual manufacturing stock to find the discrepancies.

It depends on the company to create audits or not. It is beneficial to conduct audits in manufacturing units.

A stock audit is important for manufacturing unit for the following reasons:-

A stock audit is a systemic process of inventory to ensure that match physical manufacturing stock is recorded at inventory level.